Discover the Latest Updates on Galvanized Steel Square Pipe in China

By:Admin

Introduction:

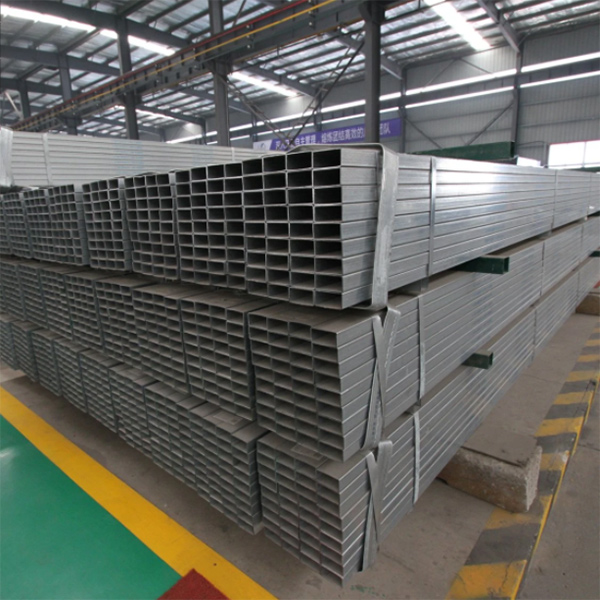

China's Galvanized Steel Square Pipe industry is witnessing a significant boost due to the advent of advanced technology and the rapid development of the manufacturing sector. With the removal of the brand name, we delve into the current state of the industry and the crucial role it plays in furthering China's infrastructure and construction projects.

Paragraph 1:

Galvanized Steel Square Pipes are an essential component in the construction industry, widely used in various applications including structural support, transportation, fencing, and scaffolding. These pipes are manufactured using high-quality steel that undergoes a galvanization process to enhance durability and resistance to corrosion.

Paragraph 2:

Combined with advanced technology, China's Galvanized Steel Square Pipe manufacturers have revolutionized the production process, ensuring enhanced quality and efficiency. The integration of computer-controlled systems and automation has enabled seamless manufacturing, precise measurements, and improved product consistency. To meet the rising demand, companies are increasingly adopting state-of-the-art machinery and equipment to stay competitive in the global market.

Paragraph 3:

China's Galvanized Steel Square Pipe industry has gained recognition for its commitment to quality and compliance with international standards. With an emphasis on product innovation and research, manufacturers are constantly improving their production techniques and adopting eco-friendly practices. This focus has propelled China to become the world's largest producer and exporter of Galvanized Steel Square Pipes.

Paragraph 4:

Driven by the nation's rapid urbanization, China's construction industry has witnessed substantial growth, leading to an increasing demand for Galvanized Steel Square Pipes. The versatility and durability of these pipes make them a suitable choice for various infrastructure projects, including residential buildings, commercial complexes, bridges, and highways.

Paragraph 5:

Moreover, Galvanized Steel Square Pipes offer several advantages over conventional steel pipes. The galvanization process provides a protective zinc coating that acts as a barrier against humidity, moisture, and corrosive elements, ensuring longevity and minimal maintenance requirements. Additionally, the square shape of these pipes aids in easy installation, thereby reducing labor costs and construction timeframes.

Paragraph 6:

Another critical factor contributing to the growth of China's Galvanized Steel Square Pipe industry is its capacity to cater to both domestic and international markets. Chinese manufacturers have established a global presence, exporting their products to various countries across Asia, Europe, and North America. This expansion has not only boosted the industry's revenue but also created employment opportunities and fostered economic growth.

Paragraph 7:

However, the industry also faces challenges such as fluctuating raw material prices, stringent regulations, and intensifying market competition. Manufacturers need to address these concerns by adopting effective supply chain management strategies and continuously investing in research and development to stay ahead of the curve.

Paragraph 8:

Looking ahead, the future appears promising for China's Galvanized Steel Square Pipe industry. The government's focus on infrastructure development, the rapid growth of the manufacturing sector, and the increasing urbanization demand will continue to drive the industry's expansion. To capitalize on these opportunities, manufacturers must embrace technological advancements, adhere to sustainable practices, and explore new avenues for growth.

Conclusion:

China's Galvanized Steel Square Pipe industry is experiencing a period of rapid growth, bolstered by technological advancements and surging demand. With a strong emphasis on quality, innovation, and sustainability, Chinese manufacturers are poised to further strengthen their position as global leaders in the production and export of Galvanized Steel Square Pipes. As this industry continues to play a vital role in China's infrastructure development, it will contribute significantly to the nation's economic progress and reinforce its reputation as a manufacturing powerhouse.

Company News & Blog

Strong Demand for Copper Bars in China Boosts Global Market Outlook

China Copper Bar (CCB) announces the release of their latest product: an ultra-high purity copper bar designed for use in advanced electronics and renewable energy applications. The new copper bar boasts a purity of 99.999% and is ideal for use in solar panels, electric vehicles, and other cutting-edge technologies.CCB is a leading manufacturer of copper products in China with over thirty years of experience in the industry. The company prides itself on its commitment to quality and sustainability, using only the highest-quality materials and implementing environmentally friendly production processes.The new copper bar, which is free from impurities such as oxygen and sulfur, is designed to meet the strict requirements of the electronics industry. It is also an ideal material for use in renewable energy applications due to its exceptional electrical conductivity and its ability to withstand high temperatures."CCB is excited to bring this new ultra-high purity copper bar to the market," said a spokesperson for the company. "We believe it will play a crucial role in the development of advanced electronics and renewable energy technologies, and we are confident that it will be well received by our customers around the world."The release of this new product comes at a time when the global demand for copper is increasing, driven in part by the growth of the renewable energy sector. According to a report by the International Energy Agency, renewable energy will account for 30% of the world's electricity generation by 2024. This growth is expected to drive demand for copper and other metals that are essential for the production of solar panels, wind turbines, and other clean energy technologies.CCB is well positioned to take advantage of this trend, with a strong focus on innovation and sustainability. The company has invested heavily in research and development, and has established a number of strategic partnerships with leading companies in the electronics and renewable energy sectors."We believe that our commitment to quality, innovation, and sustainability is what sets us apart in the market," said the spokesperson for CCB. "We are always looking for new ways to improve our products and processes, and we are excited about the role that our new ultra-high purity copper bar will play in the development of the next generation of electronics and clean energy technologies."The release of this new product is just the latest in a long line of innovations from CCB. Over the past few years, the company has introduced a number of new products and processes that have helped to position it as a leader in the copper industry. From new production techniques that reduce waste and emissions to cutting-edge products like the ultra-high purity copper bar, CCB is committed to staying at the forefront of innovation and sustainability.As demand for copper continues to grow, CCB is well positioned to meet the needs of its customers around the world. With a strong focus on quality, innovation, and sustainability, the company is poised to play a leading role in the development of the next generation of electronics and clean energy technologies.

Growing Demand for Copper Plate and Copper Sheet in China: Latest Market Insights

China Copper Plate and Copper Sheet: A Comprehensive Guide to the IndustryIn recent years, China has emerged as a major player in the global copper plate and copper sheet industry. The country's rapid industrialization, technological advancements, and skilled workforce have made it a hub for copper production and an important market for products made from this versatile metal.China Copper Plate and Copper Sheet, a leading industry player, has been at the forefront of this growth. With state-of-the-art manufacturing facilities and a commitment to quality, the company has solidified its position as a trusted supplier of copper products.Established in [year], China Copper Plate and Copper Sheet has continuously expanded its production capacity and product range to meet the growing demands of various industries, including automotive, construction, electronics, and telecommunications. The company's copper plates and sheets are known for their exceptional quality, high ductility, and excellent thermal and electrical conductivity. These attributes make them ideal for a wide range of applications, such as electrical wiring, heat exchangers, printed circuit boards, and architectural elements.China Copper Plate and Copper Sheet's commitment to sustainability is also worth mentioning. The company adheres to strict environmental standards throughout its production processes, ensuring minimal impact on the environment. By implementing advanced recycling techniques and reducing energy consumption, they contribute to the conservation of natural resources and promote greener manufacturing practices.Furthermore, China Copper Plate and Copper Sheet actively invests in research and development to stay ahead of industry trends and develop innovative copper products. Their team of skilled engineers and technicians work closely with customers to understand their unique requirements and provide customized solutions. By offering tailor-made products, the company aims to create long-lasting partnerships with customers and drive mutual growth.The company's dedication to customer satisfaction extends beyond product quality. China Copper Plate and Copper Sheet places great emphasis on maintaining reliable and efficient supply chains. They have established a robust distribution network, ensuring timely and seamless delivery of their copper products to customers both domestically and internationally.As a testament to their success, China Copper Plate and Copper Sheet has received numerous certifications and accolades over the years. These include ISO 9001:2015, ISO 14001:2015, and OHSAS 18001:2007, which demonstrate their commitment to quality, environmental sustainability, and occupational health and safety. These certifications serve as a testament to the company's unwavering pursuit of excellence and their focus on meeting and exceeding industry standards.Looking ahead, China Copper Plate and Copper Sheet plans to further expand its market presence and enhance its product portfolio. The company recognizes the dynamic nature of the industry and is dedicated to staying at the forefront of technological advancements and industry trends. By continuously investing in research and development and collaborating with customers, they strive to develop innovative copper products that meet evolving market demands.In conclusion, China Copper Plate and Copper Sheet has played a pivotal role in the growth of the copper plate and copper sheet industry in China. Through their unwavering commitment to quality, sustainability, and customer satisfaction, the company has established itself as a trusted supplier both domestically and internationally. With their focus on innovation and adaptability, China Copper Plate and Copper Sheet is well-positioned to lead the industry into a new era of growth and development.

High-Quality 202 Stainless Steel Pipe Suppliers Available Now for Sale

Title: Leading Stainless Steel Pipe Suppliers Offer High-Quality 202 Grade Products Introduction: The stainless steel industry has witnessed significant growth in recent years, driven by the increasing demand for durable and corrosion-resistant materials across various sectors. In this context, 202 Stainless Steel Pipe Suppliers have emerged as leading market players, offering high-quality products to cater to diverse customer needs. With their expertise and commitment to exceptional service, these suppliers have gained a strong foothold in the industry.Industry Outlook and Demand for Stainless Steel Pipes:Stainless steel pipes serve as critical components in industries such as construction, automotive, and manufacturing due to their durable nature and resistance to corrosion. The global stainless steel pipe market has seen a surge in demand in recent years, driven by increased construction activities, infrastructure development, and rising urbanization.Featuring excellent weldability and formability, stainless steel pipes are widely sought after for applications ranging from conveyance of fluids and gases to structural supports. Additionally, the 202 grade stainless steel pipes, specifically, offer remarkable resistance to high temperatures, making them ideal for applications in chemical industries, oil refineries, and power plants.Meeting Industry Needs - Introduction of 202 Stainless Steel Pipe Suppliers:In this dynamic market scenario, one company stands out as a reliable and prominent supplier of high-quality 202 grade stainless steel pipes. With a commitment to customer satisfaction and adherence to strict quality standards, this leading supplier has garnered a reputation for excellence in the industry.Their extensive product lineup includes a wide range of 202 grade stainless steel pipes, available in various sizes and specifications to cater to different customer requirements. Utilizing advanced manufacturing techniques, the company ensures that their products exhibit exceptional tensile strength, impact resistance, and durability.Quality Assurance and Compliance:The 202 Stainless Steel Pipe Suppliers pride themselves on their unwavering commitment to delivering superior quality products. Employing state-of-the-art testing facilities and strict quality control measures, they ensure that each pipe meets international standards for dimensional accuracy, surface finish, and mechanical properties.The company's adherence to industry certifications, such as ISO 9001, further demonstrates their commitment to delivering unparalleled quality. Additionally, they employ a team of highly skilled professionals who possess extensive knowledge and experience in stainless steel manufacturing, guaranteeing the flawless fabrication of their pipes.Collaboration with Clients and Focus on Customer Satisfaction:Understanding the importance of client collaboration, this reputed supplier actively engages with customers to comprehend their unique requirements. By developing a strong relationship based on trust and mutual understanding, they provide tailored solutions, ensuring customer satisfaction at every stage of the process.Their customer-centric approach extends beyond the sale, as they support clients with prompt delivery, efficient customer service, and technical assistance. Additionally, the supplier maintains an extensive inventory to streamline the supply chain process, ensuring timely and reliable deliveries.Conclusion:The 202 Stainless Steel Pipe Suppliers have emerged as reliable market leaders, offering high-quality products to meet the increasing demand for stainless steel pipes in various industries. With their commitment to excellence, extensive product range, stringent quality control, and dedication to customer satisfaction, they have established a strong presence in the market.In an era where durability, corrosion resistance, and cost-effectiveness are prized qualities, these suppliers continue to excel, positioning themselves as trusted partners for all stainless steel pipe needs.

How to Choose and Use Square Tubes for Your DIY Projects

article about the increasing demand and versatility of square tubes in various industries.Square tubes have become an increasingly popular choice among construction and manufacturing industries due to their durability and versatility. The unique shape of square tubes offers numerous advantages over traditional cylindrical tubes, making them the preferred choice in a variety of applications.The demand for square tubes has been on the rise in recent years, and for good reason. Square tubes have a higher load-bearing capacity compared to round tubes, making them an ideal choice for a wide range of construction applications. They are also more resistant to buckling, which makes them an ideal choice for use in structural applications.However, the benefits of square tubes extend beyond just construction. In fact, the versatility of square tubes has led to their widespread use across many different industries. Square tubes are utilized in industries like automotive, agricultural, industrial equipment, and even in the food and beverage industry.In the automotive industry, square tubes are used for various applications, including frame rails, roll cage structures, and engine mounts. Their ability to withstand high levels of stress and pressure make them an ideal choice for these applications. Square tubes are also lightweight, which makes them an ideal choice for automobile manufacturers who are always looking to reduce weight to improve fuel efficiency.Meanwhile, The agricultural industry utilizes square tubes for high-stress applications such as plow frames, seed drill frames, and fertilizer tanks. Additionally, square tubing has also become a popular choice for gates and panels in the agricultural industry. The sturdy nature of square tubes makes them ideal for agricultural applications, where heavy loads and rough conditions are common.Moreover, the food and beverage industry uses square tubes in a variety of applications. Square tubes are used to manufacture food storage containers, tanks, and conveyor systems. Due to their strength and corrosion resistance, they are also used for food processing equipment.Finally, the versatility of square tubes has led to their use in industrial equipment, including material handling equipment, conveyors, and hydraulic power systems. Their strength and load-bearing capacity make them ideal for these applications.Square tubes are also known for their versatility in architectural designs. They offer an aesthetically pleasing look and can be customized to suit different preferences. This is particularly beneficial for architects and builders who want to create unique structures that stand out from the rest.In addition to their versatility, square tubes also offer other benefits such as resistance to warping, twisting, and bending. This durability allows square tubes to withstand harsh weather conditions and extreme temperatures without becoming weakened. They are also corrosion-resistant, making them ideal for marine and outdoor applications.With their versatility, durability, and flexibility, it is no wonder that the demand for square tubes has been on the rise. Their unique shape and numerous advantages have made square tubes the go-to choice for many different applications. As the demand for efficient, cost-effective, and durable materials continues to rise in various industries, the popularity of square tubes is expected to continue to increase.

Unveiling the Dark and Thrilling World of Black Metal Tube: Exploring the Subgenre's Intriguing Culture Beyond the Music

Title: Exploring the Remarkable Advancements in Innovative Metal Tube TechnologyIntroduction:Metal tube technology has seen incredible advancements in recent years, revolutionizing a wide range of industries and applications. In particular, the development of the Black Metal Tube (name removed), by a leading company in the field, has garnered significant attention. With a commitment to excellence and innovation, this cutting-edge company has propelled the metal tube industry forward, delivering remarkable products that meet the demands of modern manufacturing processes. In this article, we will delve into the intricate features, applications, and benefits of their pioneering metal tube technology.1. Exceptional Material Composition:The Black Metal Tube boasts a unique composition, combining a proprietary blend of metals that enhance its strength, durability, and resistance to corrosion. This special formulation ensures that the tubes remain structurally stable even under extreme conditions, making them suitable for a wide array of industrial applications.2. Enhanced Manufacturing Techniques:Employing state-of-the-art manufacturing processes, this leading company has perfected the production of their metal tubes. The use of cutting-edge technologies, such as precision laser cutting and robotic welding, enables consistent quality, precise dimensions, and optimal performance in their products. These improved manufacturing techniques ensure superior tube reliability and guarantee the adherence to strict industry standards.3. Versatile Applications:The Black Metal Tube finds versatile applications across various sectors, including automotive, aerospace, construction, and manufacturing. In automotive industries, the tubes are used in the fabrication of exhaust systems and chassis components, providing exceptional durability and thermal stability. Similarly, in the aerospace field, the Black Metal Tube's light yet sturdy construction makes it an ideal choice for aircraft structural components, reducing weight and improving fuel efficiency.Moreover, the tubes find extensive use in the construction industry, offering robust support for structures like bridges and high-rise buildings. The corrosion-resistant properties of the Black Metal Tube make it a reliable option, even in harsh environmental conditions. Additionally, in the manufacturing sector, these tubes are integral to the production of machinery and equipment due to their strength, reliability, and ease of customization.4. Energy-Efficient Solutions:The Black Metal Tube contributes significantly to energy conservation efforts. By replacing traditional materials with these innovative tubes in various applications, industries can achieve improved energy efficiency and reduced environmental impact. For instance, in the renewable energy sector, the tubes prove invaluable in the construction of wind turbine towers, ensuring reliable support in extreme weather conditions.5. Sustainability and Recycling:In line with modern environmental directives and concerns, the Black Metal Tube is designed with sustainability in mind. Alongside their outstanding durability, these metal tubes are recyclable and contribute to reducing carbon footprints. The company actively supports responsible metal recycling initiatives, further emphasizing their commitment to environmental preservation.6. The Future of Metal Tube Technology:Looking forward, the company continues to invest in research and development to advance metal tube technology even further. With ongoing efforts to enhance the material properties, optimize manufacturing processes, and expand their product range, the company aims to remain at the forefront of innovation in the industry.Conclusion:The Black Metal Tube, developed by a leading company in the field, represents a remarkable example of innovative metal tube technology. Its exceptional material composition, advanced manufacturing techniques, versatile applications, energy-efficient solutions, and commitment to sustainability make it an indispensable choice across numerous sectors. As the company continues to push the boundaries of metal tube technology, the future holds great promise for further advancements in this field, facilitating progress in industries worldwide.

Discover the Latest Updates and Trends in Aluminum Coil Manufacturing from China

China Aluminum Coil: A Rising Industry Leader in the Global MarketIntroduction: China Aluminum Coil, a prominent player in the global aluminum industry, has been making waves in recent times. With advancements in technology, increased production capacity, and a strong commitment to quality, the company has emerged as a frontrunner in the highly competitive global market. This news article provides an overview of China Aluminum Coil, highlighting its key strengths, market dominance, and future prospects.Established in 2002, China Aluminum Coil has quickly emerged as a leading manufacturer and exporter of aluminum coils, sheets, and strips. The company's state-of-the-art production facilities, equipped with cutting-edge machinery, enable them to produce a wide range of high-quality aluminum products that cater to varying industry requirements. China Aluminum Coil's commitment to innovation and continuous improvement has propelled its growth and positioned it as a preferred supplier for domestic and international customers.Market Dominance:A significant reason for China Aluminum Coil's success is its dominant position in the global market. The company has established an extensive distribution network spanning across more than 80 countries, allowing it to reach customers worldwide. Moreover, China Aluminum Coil's reputation for reliability, product consistency, and competitive pricing has made it a preferred partner for many large-scale construction, automotive, and aerospace projects globally.Quality Assurance:China Aluminum Coil places utmost importance on quality assurance. The company follows strict quality management systems and has obtained ISO 9001 certification for its production and supply chain processes. This commitment to quality ensures that customers receive only the finest aluminum products that conform to international standards.Innovation and Sustainable Practices:Embracing innovation, China Aluminum Coil consistently invests in research and development to enhance its product offerings. The company's dedicated team of engineers works tirelessly to develop new alloys, improve manufacturing processes, and cultivate the use of lightweight aluminum in various industries. By prioritizing sustainability, China Aluminum Coil aims to minimize its environmental impact, adopt energy-efficient technologies, and promote a greener product portfolio.Partnerships and Collaborations:Recognizing the importance of strategic partnerships, China Aluminum Coil actively collaborates with industry leaders, research institutions, and technology providers. These collaborations facilitate knowledge sharing, enable access to the latest market trends, and foster long-term growth opportunities. By fostering an environment conducive to collaborative innovation, China Aluminum Coil stays ahead of the curve, adapting swiftly to changing market demands.Future Prospects:The future looks promising for China Aluminum Coil as it continues to expand its market share and strengthen its global position. With the rise in demand for lightweight and durable aluminum products, the company is well-positioned to capitalize on the opportunities presented by the construction, automotive, and aerospace sectors. Furthermore, as global environmental regulations tighten, the company's commitment to sustainability will serve as a competitive advantage.Conclusion:China Aluminum Coil's rise to prominence in the global aluminum industry is a testament to its unwavering commitment to quality, innovation, and customer satisfaction. As it continues to invest in advanced technology, expand its distribution network, and forge strategic collaborations, the company is poised to achieve even greater heights in the future. With a strong foundation built on excellence and sustainability, China Aluminum Coil is undoubtedly a rising industry leader in the global market.

Latest Updates on the Steel Used in the L360 Pipeline

The L360 pipeline steel has been widely recognized as one of the best materials used in the construction of pipelines. By incorporating the latest technological advancements in steel production, the L360 pipeline steel is stronger, more durable, and more resistant to corrosion than any other type of steel. This has made it the preferred choice for industries that require high-quality pipelines.The L360 pipeline steel is a product of industry leaders who have worked tirelessly to create a product that meets the highest quality standards. In addition to its durability, strength, and corrosion resistance, the L360 pipeline steel is also environmentally friendly. Companies that use this type of steel product are, therefore, able to meet their sustainability goals while also meeting their production needs.One such company that has been at the forefront of producing top-quality L360 pipeline steel products is {brand name removed}. {Brand name removed} has been in operation for many years, and during this time, it has established itself as a market leader in the production of steel products. The company has a wide range of steel products that are designed to meet the diverse needs of its clients.{Brand name removed} has a state-of-the-art facility that is equipped with modern steel production machinery. The company also has a team of highly skilled professionals who are dedicated to ensuring that all the steel products produced are of the highest quality. These professionals are continuously trained and updated on the latest technological advancements in steel production to ensure that they can provide clients with the best products.The L360 pipeline steel produced by {Brand name removed} is of the highest quality. The company uses the latest technological advancements in steel production to create a product that is strong, durable, and resistant to corrosion. This makes it ideal for use in the construction of pipelines that are required to transport different types of materials over long distances.One of the most significant advantages of using L360 pipeline steel is that it is environmentally friendly. The steel is produced using a process that is designed to reduce the carbon footprint of steel production. This means that companies using this product can meet their sustainability goals while also meeting their production needs.{Brand name removed} has a reputation for delivering high-quality products on time and within budget. The company works closely with its clients to ensure that their specific needs are met. This includes helping clients to select the right steel product for their needs and providing them with technical support throughout the production process.In conclusion, the L360 pipeline steel is an excellent product that is ideal for industries that require high-quality pipelines. {Brand name removed} is a market leader in the production of this type of steel product. The company has a state-of-the-art facility, a team of highly skilled professionals, and the latest technological advancements in steel production. By working closely with its clients, {Brand name removed} has been able to deliver high-quality products that meet the specific needs of its clients. Companies that require high-quality pipelines should consider using L360 pipeline steel from {brand name removed}.

Seamless Welded and Stainless Steel Sheet Market Experiences Growth in China

China's Seamless Welded and Stainless Steel Sheet Industry Soars to New HeightsChina, known for its prowess in industrial production, has once again made a significant stride in the steel manufacturing sector. The country's seamless welded and stainless steel sheet industry has witnessed an unprecedented surge, setting new records and captivating the attention of global markets.China's seamless welded and stainless steel sheet industry has a rich history, dating back several decades. Over the years, the industry has continuously evolved to meet the growing demands of various sectors such as construction, automobile, energy, and more. Today, it stands tall as a global leader, providing high-quality steel products to both domestic and international markets.One of the prominent players in this thriving industry is {}. Founded in {}, the company has been at the forefront of manufacturing and supplying top-notch seamless welded and stainless steel sheets. Recognized for their commitment to quality and innovation, {}, has played a pivotal role in shaping the industry's growth trajectory.The seamless welded steel sheets produced by {} are meticulously manufactured using advanced technologies and state-of-the-art equipment. This ensures the products' adherence to international quality standards, promoting reliability and trust among customers. With a strong emphasis on research and development, the company constantly refines its manufacturing processes and explores new techniques to enhance product offerings further.In addition to seamless welded steel sheets, {} is also a leading producer of stainless steel sheets. The company's stainless steel products are revered for their superior corrosion resistance, durability, and aesthetic appeal. These attributes make them the material of choice in applications where hygiene and appearance are of utmost importance, such as the food and beverage industry and architectural designs.One of the key factors driving the extraordinary growth of China's seamless welded and stainless steel sheet industry is the country's booming construction sector. As China continues to urbanize rapidly, the demand for steel products, particularly for infrastructure development, has skyrocketed. The industry has adeptly capitalized on this demand surge by ensuring a steady supply of high-quality steel products to meet the construction industry's needs.Moreover, China's automotive industry, one of the world's largest, has also contributed significantly to the industry's success. As automakers strive to manufacture lightweight vehicles without compromising on safety, the demand for high-strength steel sheets has soared. China, with its extensive manufacturing capabilities, has become a preferred supplier of these specialized steel products.Furthermore, the energy sector has emerged as another vital source of demand for seamless welded and stainless steel sheets. With China's commitment to transitioning to cleaner fuels and renewable energy sources, the country has witnessed a surge in infrastructure development in the solar, wind, and nuclear energy sectors. Steel sheets, known for their durability and resistance to harsh environmental conditions, play a crucial role in these projects.China's dominance in the global seamless welded and stainless steel sheet market is further bolstered by its well-established distribution network. The country's strategic location, coupled with its efficient logistics infrastructure, allows for seamless transportation of steel products to various corners of the world. This has enabled China to tap into overseas markets, establishing itself as a reliable supplier of high-quality steel sheets.Looking ahead, the future of China's seamless welded and stainless steel sheet industry seems promising. As the country strives to attain environmental sustainability and nurture innovation, the industry is poised to witness continued growth. With companies like {} leading the charge, China's steel manufacturing sector is set to soar to even greater heights, cementing its position as a global steel powerhouse.

Affordable Coil Tubing Manufacturers for Grades 201, 304, and 316: A Comprehensive Overview

Title: Leading Grade Coil Tubing Manufacturers Revolutionize the Industry with Affordable PricesIntroduction (100 words):Grade coil tubing is an essential component in various industrial processes. With the aim to provide cost-effective and high-quality products, leading manufacturers have emerged with 201, 304, and 316 grade coil tubing at competitive prices. By leveraging cutting-edge technology, innovative production methods, and an unwavering commitment to customer satisfaction, these manufacturers have set a new benchmark in the coil tubing industry.Company Profiles (200 words):Manufacturer A, a renowned industry leader, specializes in producing high-grade coil tubing solutions. With years of experience and expertise, they have gained a reputation for offering top-notch quality products. Their advanced manufacturing facilities and rigorous quality control measures ensure the durability and reliability of their 201, 304, and 316 grade coil tubing. By exercising strict adherence to international standards, Manufacturer A guarantees their customers receive the finest coil tubing products available on the market.Manufacturer B, backed by a strong and experienced team, has established itself as a prominent player in the coil tubing industry. Their state-of-the-art manufacturing facilities enable them to produce a wide range of grade coil tubing options, catering to diverse industrial needs. With a focus on customer satisfaction, Manufacturer B aims to provide cost-effective solutions without compromising on quality. Adhering to stringent quality control processes, they ensure their products exceed industry standards.Manufacturer C, with its commitment to innovation and quality, has been at the forefront of producing superior grade coil tubing. Their team of experienced engineers is dedicated to developing cutting-edge manufacturing techniques, resulting in reliable and durable 201, 304, and 316 grade coil tubing. They prioritize customer needs and satisfaction, making them a trusted choice in the industry. Upholding highest production standards, Manufacturer C continues to deliver exceptional coil tubing solutions.Affordable Pricing and Quality Assurance (300 words):In response to increasing market demand, leading grade coil tubing manufacturers have responded by offering affordable prices without compromising on quality. By streamlining their production processes, leveraging economies of scale, and implementing cost-saving strategies, these manufacturers have made top-quality coil tubing more accessible to a wider customer base. This affordability is particularly significant considering the premium nature of 201, 304, and 316 grade coil tubing.Despite the competitive pricing, manufacturers ensure that all products undergo stringent quality control checks. Extensive testing procedures, including material composition analysis, dimensional accuracy, and corrosion resistance assessments, are carried out to guarantee that the tubing meets or exceeds industry standards.The 201, 304, and 316 grade coil tubing offered by these manufacturers possess exceptional mechanical properties, corrosion resistance, heat resistance, and versatility, making them suitable for various industrial applications. Whether it be in oil and gas, chemical processing, or construction industries, the coil tubing provides durability, reliability, and longevity.Furthermore, the manufacturers prioritize customer satisfaction and take great care in understanding their unique needs. With prompt technical support and dedicated customer service, these manufacturers ensure that inquiries, issues, and customization requests are handled efficiently, providing a seamless experience for their customers.Conclusion (200 words):The emergence of leading grade coil tubing manufacturers offering 201, 304, and 316 grade coil tubing at competitive prices has revolutionized the industry. By prioritizing affordability, these manufacturers have opened new avenues for businesses across multiple sectors to access high-quality coil tubing without compromising on performance.Through the use of state-of-the-art manufacturing facilities and stringent quality control processes, these manufacturers have proven their commitment to delivering reliable and durable products that meet or exceed industry standards. Their dedication to innovation and customer satisfaction further strengthens their position in the market.With the availability of affordable coil tubing options, businesses in sectors such as oil and gas, chemical processing, and construction can now improve their operational efficiency and reduce costs. The accessible pricing, combined with the exceptional mechanical properties and corrosion resistance of the 201, 304, and 316 grade coil tubing, ensures that customers receive the best value and longevity from their investment.As these manufacturers continue to set new benchmarks in the industry, it is expected that the coil tubing market will witness significant growth and advancements in the coming years, supporting further innovation and technological progress across multiple industrial sectors.

The Latest Updates on Seamless Coil Tube for Stainless Steel

Stainless Steel Seamless Coil Tube: A Promising Solution for Multiple IndustriesWhen it comes to creating reliable, efficient, and durable solutions for various industries, stainless steel remains the go-to material for many manufacturers. Its exceptional corrosion resistance, high strength, and aesthetic appeal make it an ideal choice for a wide range of applications. Stainless steel seamless coil tubes, in particular, have gained significant popularity due to their versatility and ability to handle extreme conditions. In this article, we will delve into the benefits and applications of stainless steel seamless coil tubes, showcasing their importance in industries worldwide.Stainless steel seamless coil tubes are manufactured through a meticulous process that involves forming a continuous tube from a single stainless steel strip. The absence of any welded joints makes these tubes highly resistant to leakage and ensures a seamless flow of fluids or gases, making them ideal for critical applications. Additionally, the seamless construction ensures exceptional strength and durability, allowing these tubes to withstand high pressures and temperatures.One of the industries that highly benefits from stainless steel seamless coil tubes is the oil and gas sector. These tubes are widely used in the exploration, production, and transportation of oil and gas, where their corrosion resistance and high pressure capabilities ensure the safety and efficiency of operations. Seamless coil tubes are also commonly employed in heat exchangers, condensers, and boilers, where their ability to handle extreme temperature fluctuations is crucial.The pharmaceutical and chemical industries also rely heavily on stainless steel seamless coil tubes. In pharmaceutical manufacturing, these tubes are used for various processes such as fluid transfer, heating, and cooling. The seamless construction of these tubes ensures the purity and integrity of the fluids being transported, thus meeting the stringent quality standards required in pharmaceutical production. Likewise, in the chemical industry, stainless steel seamless coil tubes are used in reactors, distillation columns, and other equipment, providing a corrosion-resistant and reliable solution for the storage and transportation of a wide range of chemicals.The food and beverage industry is yet another sector where stainless steel seamless coil tubes find extensive applications. From dairy processing to breweries and wineries, these tubes are used for fluid transfer, heating, and cooling purposes. The hygienic properties of stainless steel, coupled with the seamless construction of these tubes, make them an ideal choice for maintaining the quality and purity of food and beverage products.In addition to these industries, stainless steel seamless coil tubes are also utilized in automotive, aerospace, and construction sectors. In automotive manufacturing, these tubes are used for fuel and brake lines, as well as heat exchangers. The aerospace industry benefits from the high strength and corrosion resistance of seamless coil tubes in applications such as hydraulic systems and fuel lines. Similarly, in the construction sector, stainless steel seamless coil tubes are employed for plumbing, heating, and ventilation systems, where durability and reliability are paramount.In conclusion, stainless steel seamless coil tubes have become an indispensable component in various industries. Their corrosion resistance, high strength, and seamless construction make them a reliable and efficient solution for critical applications. From the oil and gas sector to pharmaceuticals, food and beverage, automotive, aerospace, and construction industries, these tubes continue to fuel progress and innovation worldwide. As manufacturers continue to enhance their production processes, stainless steel seamless coil tubes are expected to play an even more significant role in shaping the industries of the future.