Standards: ASTM, AISI, DIN, EN, GB, JIS

Place of origin: shandong China (Mainland)

Brand name: SH

Model number: SH-03-08

Type: seamless

Steel grade: 300 series 600series 800 series

Application: uesd in precision instruments and

Thickness: 0.05-6.5mm

Outer diameter:3.18mm-51mm

Welding line type: BV

Outer diameter: 6-50.8mm

Thickness: 0 .2-3mm

Packaging detail: wooden case for stainless steel tube

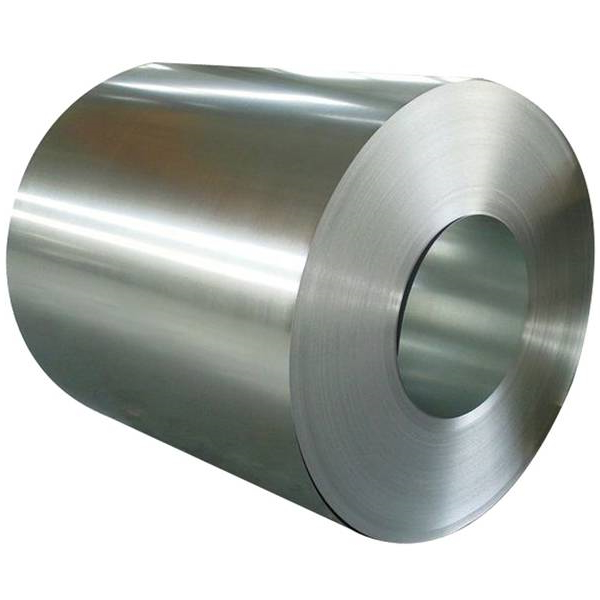

Packaging: wrapped in shaft and packed with plastic or custom packing

Specifications: Stainless steel coiled tubing

Max : 3500M per piece according to customer requirements.

Tolerance range: diameter: + 0.1mm, wall thickness: + 10%, length: -0/+6mm

Tolerance: OD± 0.1mm, wall thickness: ±10%, length: ±5mm

application : refrigeration equipment, evaporator,

gas liquid delivery, condenser, beverage machine

State: soft / half hard / soft bright annealing

Product advantages: surface polishing and fine, uniform wall thickness, tolerance precision etc..

Commonly Size of stainless steel coiled tube: we can product them as your request

| Please refer to grade and product form adjustment factors below. | |||||||||||||||

| Outside diameter, in. | Wall thickness, in. | Working pressure2) | Burst pressure2) | Collapse pressure4) | |||||||||||

| psi (MPa) | psi (MPa) | psi (MPa) | |||||||||||||

| 1/4 | 0.035 | 6,600 (46) | 22,470 (155) | 6,600 (46) | |||||||||||

| 1/4 | 0.049 | 9,260 (64) | 27,400 (189) | 8,710 (60) | |||||||||||

| 1/4 | 0.065 | 12,280 (85) | 34,640 (239) | 10,750 (74) | |||||||||||

| 3/8 | 0.035 | 4,410 (30) | 19,160 (132) | 4,610 (32) | |||||||||||

| 3/8 | 0.049 | 6,170 (43) | 21,750 (150) | 6,220 (43) | |||||||||||

| 3/8 | 0.065 | 8,190 (56) | 25,260 (174) | 7,900 (54) | |||||||||||

| 3/8 | 0.083 | 10,450 (72) | 30,050 (207) | 9,570 (66) | |||||||||||

| 1/2 | 0.049 | 4,630 (32) | 19,460 (134) | 4,820 (33) | |||||||||||

| 1/2 | 0.065 | 6,140 (42) | 21,700 (150) | 6,200 (43) | |||||||||||

| 1/2 | 0.083 | 7,840 (54) | 24,600 (170) | 7,620 (53) | |||||||||||

| 5/8 | 0.049 | 3,700 (26) | 18,230 (126) | 3,930 (27) | |||||||||||

| 5/8 | 0.065 | 4,900 (34) | 19,860 (137) | 5,090 (35) | |||||||||||

| 5/8 | 0.083 | 6,270 (43) | 26,910 (151) | 6,310 (44) | |||||||||||

| 3/4 | 0.049 | 3,080 (21) | 17,470 (120) | 3,320 (23) | |||||||||||

| 3/4 | 0.065 | 4,090 (28) | 18,740 (129) | 4,310 (30) | |||||||||||

| 3/4 | 0.083 | 5,220 (36) | 20,310 (140) | 5,380 (37) | |||||||||||

| 1) Estimates only. Actual pressures should be calculated considering all stress factors in the system. | |||||||||||||||

| 2) Based on calculations from API 5C3, using a wall tolerance of +/-10% | |||||||||||||||

| 3) Based on ultimate strength burst calculations from API 5C3 | |||||||||||||||

| 4) Based on yield strength collapse calculations from API 5C3 | |||||||||||||||

| Adjustment factors for working pressure limits1) | |||||||||||||||

| Pw = reference working pressure rating for TP 316L at 100°F (38°C). To determine working pressure for grade/temperature combination, multiply Pw by adjustment factor. | |||||||||||||||

| Grade | 100°F | 200°F | 300°F | 400°F | |||||||||||

| (38°C) | (93°C) | (149°C) | (204°C) | ||||||||||||

| TP 316L, seamless | 1 | 0.87 | 0.7 | 0.63 | |||||||||||

| TP 316L, welded | 0.85 | 0.74 | 0.6 | 0.54 | |||||||||||

| Alloy 825, seamless | 1.33 | 1.17 | 1.1 | 1.03 | |||||||||||

| Alloy 825, welded | 1.13 | 1.99 | 1.94 | 0.88 | |||||||||||

| 1) Adjustment factors based on allowable stress in ASME. | |||||||||||||||

| Adjustment factors for burst pressure limits1) | |||||||||||||||

| Pb = reference burst pressure for TP 316L at 100°F. To determine burst pressure for grade/temperature combination, multiply Pb by adjustment factor. | |||||||||||||||

| Grade | 100°F | 200°F | 300°F | 400°F | |||||||||||

| (38°C) | (93°C) | (149°C) | (204°C) | ||||||||||||

| TP 316L, seamless | 1 | 0.93 | 0.87 | 0.8 | |||||||||||

| TP 316L, welded | 0.85 | 0.79 | 0.74 | 0.68 | |||||||||||

| Alloy 825, seamless | 1.13 | 1.07 | 1 | 0.87 | |||||||||||

| Alloy 825, welded | 0.96 | 0.91 | 0.85 | 0.74 | |||||||||||

| 1) Adjustment factors based on ultimate strength in ASME. | |||||||||||||||