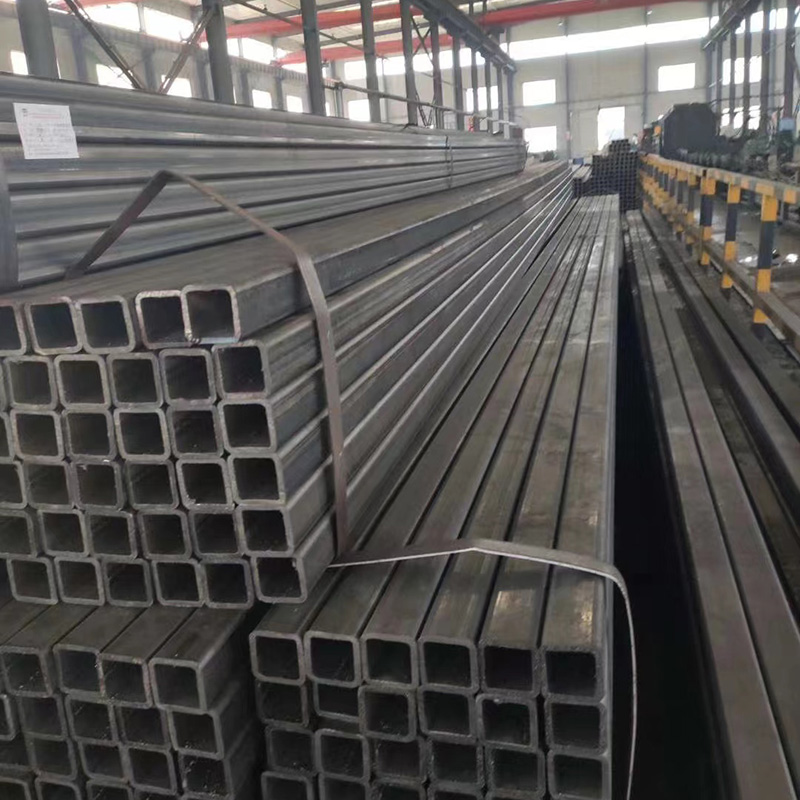

Steel Grade: A53 Gr. A, Gr B, A106 GR.A GR.B A333 GR1 GR3 GR6 S355JR S355JO 355J2 Outer Diameter: 20X20-600X600 Wall Thickness: 1mm-40mm Length: Random Length, SRL, DRL(4-14M) End:pland ends Packing:Light oiled,bundlesASTM A53 Square pipe according to the production process: hot rolled seamless square tube, cold drawn seamless square tube, squeeze seamless square tube, welded square tube. Welding square tubes are divided into: (a) arc welding square tubes, resistance welding square tubes (high frequency, low frequency), Gas welding square pipe, furnace welding square pipe (b) According to the weld, it is divided into one - straight seam welded square pipe and spiral welded square pipe1.What kind of work does your company do? Our company is a professional manufacturer. We mainly produces steel sheet/pipe/coil/lead round bars,as well as galvanized plate/pipe/coil/lead wire/corrugated sheet,etc. 2.Do you provide free samples? Yes, we can provide free sample for testing,buyer should bear all the shipping costs. 3.How long is your delivery time? Generally it is 3-7 days if the goods are in stock or it is 7-15 days if the goods are not in stock, it is according to quantity. 4.How can we guarantee quality? Always a pre-production sample before mass production;always final Inspection before shipment.And we can also accept the third-party inspection and quarantine. 5.Why should you buy from us not from other suppliers? Diversified products, direct supply from manufacturer.

Steel Grade: A53 Gr. A, Gr B, A106 GR.A GR.B A333 GR1 GR3 GR6 S355JR S355JO 355J2 Outer Diameter: 20X20-600X600 Wall Thickness: 1mm-40mm Length: Random Length, SRL, DRL(4-14M) End:pland ends Packing:Light oiled,bundlesASTM A53 Square pipe according to the production process: hot rolled seamless square tube, cold drawn seamless square tube, squeeze seamless square tube, welded square tube. Welding square tubes are divided into: (a) arc welding square tubes, resistance welding square tubes (high frequency, low frequency), Gas welding square pipe, furnace welding square pipe (b) According to the weld, it is divided into one - straight seam welded square pipe and spiral welded square pipe1.What kind of work does your company do? Our company is a professional manufacturer. We mainly produces steel sheet/pipe/coil/lead round bars,as well as galvanized plate/pipe/coil/lead wire/corrugated sheet,etc. 2.Do you provide free samples? Yes, we can provide free sample for testing,buyer should bear all the shipping costs. 3.How long is your delivery time? Generally it is 3-7 days if the goods are in stock or it is 7-15 days if the goods are not in stock, it is according to quantity. 4.How can we guarantee quality? Always a pre-production sample before mass production;always final Inspection before shipment.And we can also accept the third-party inspection and quarantine. 5.Why should you buy from us not from other suppliers? Diversified products, direct supply from manufacturer.| ASTM A53 /A106 Chemical Components and Machanical Property | |||||||||||||

| Standard | Steel Grade | Chemical Components | Machanical Property | ||||||||||

| C | Mn | P | S | Cu | Ni | Cr | Mo | V | Tensile Strength (Mpa) | Yield Strength(Mpa) | Elongation (Mpa) | ||

| ASTM A53 | A | ≤0.25 | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥330 | ≥205 | ≥29.5 |

| B | ≤0.30 | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥415 | ≥240 | ≥29.5 | |

| Standard | Steel Grade | Chemical Components | Machanical Property | ||||||||||

| C | Si | Mn | P | S | Cu ,Ni | Cr | Mo | V | Tensile Strength (Mpa) | Yield Strength(Mpa) | Elongation (Mpa) | ||

| ASTM A106 | B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥415 | ≥240 | ≥30 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥485 | ≥275 | ≥30 | |