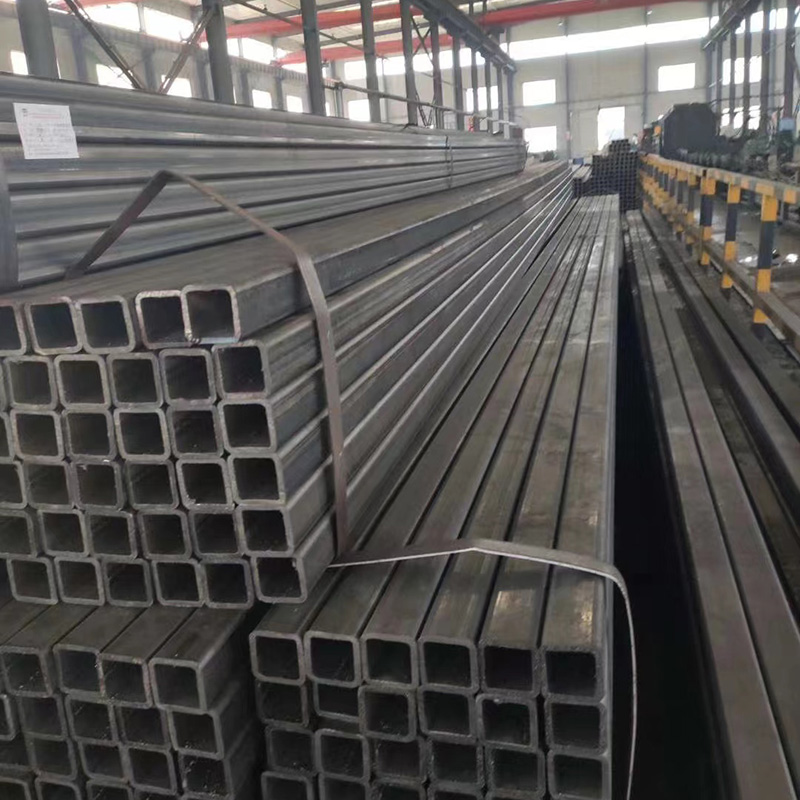

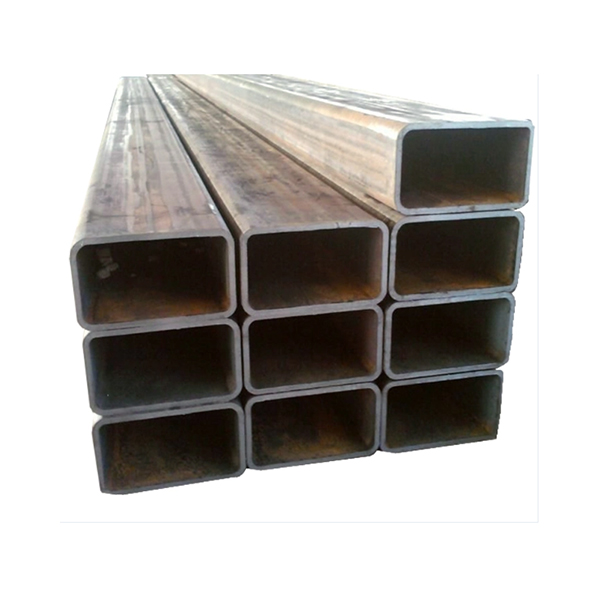

Rectangular black steel tubing A large number of pipeline used for conveying fluid, such as oil, natural gas, water, gas, steam, etc., in addition, in bending, torsion strength at the same time, lighter weight, so also widely used in manufacturing machinery parts and engineering structures. Also commonly used for the production of conventional weapons, gun barrels, shells and so on. Rectangular black steel tubing It is often used in all kinds of building structures and engineering structures, such as beams, Bridges, power transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves, etc.Cold-drawn rectangular tube, as the starting raw material is a hot rolled strip coil, in use, first with an acid, the oxide skin absorption, and then cold rolling, so that the production of the cold rolled steel tube, hardness and strength, but the toughness will be slightly reduced. Therefore, this will lead to a reduction in performance at the time of stamping, and cold rolled rectangular tube production can only be simply deformed parts manufacturers. Cold rolling, after continuous annealing process. Square tube, cold rolled production quality, as well as surface appearance, as well as the accuracy of the size of hot rolled rectangular tube is better than the above, the thickness is much thinner, so has been favored by many manufacturers. Many industries, on the other hand, are very widely used. Many defects of square tube are caused in the perforation process, so the perforation process in the blank is the key procedure in the production of square tube. The main difficulty of high alloy perforation lies in its low perforation performance. Small amount of compression will cause the perforation process is not stable, so the critical pressure shrinkage when the head should be in front of the compression of the general set at about seven percent, otherwise it will not bite, or even move to increase or before the card. An increase in compression in front of the head will also form a cavity and sink defects inside the sound. Therefore, if you want to overcome the problem, the tube blank should be centered, and the empty depth of centering should be compared according to other steel types. Hot-rolled rectangular tubes, continuous casting billets, and rolled plates as raw materials, and then through the heating furnace, even in the use of high pressure water, the surface of phosphorus removal work, and then with a roughing mill, in the roughing mill is mainly cut off the head and tail of the rectangular tubes, and then in the pipeline, and then fed to the finishing mill, computer-controlled precision rolling. After the square tube is cooled by laminar flow, the coiler is rolled and then crimped. However, when re-crimping, the thickness often appears as well as something of an error in accuracy. This is no different from the edges are also prone to flaws. Then crimping again, trim with straightening treatment after the cutting head, after that to ensure the thickness and accuracy of the tube.

Rectangular black steel tubing A large number of pipeline used for conveying fluid, such as oil, natural gas, water, gas, steam, etc., in addition, in bending, torsion strength at the same time, lighter weight, so also widely used in manufacturing machinery parts and engineering structures. Also commonly used for the production of conventional weapons, gun barrels, shells and so on. Rectangular black steel tubing It is often used in all kinds of building structures and engineering structures, such as beams, Bridges, power transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves, etc.Cold-drawn rectangular tube, as the starting raw material is a hot rolled strip coil, in use, first with an acid, the oxide skin absorption, and then cold rolling, so that the production of the cold rolled steel tube, hardness and strength, but the toughness will be slightly reduced. Therefore, this will lead to a reduction in performance at the time of stamping, and cold rolled rectangular tube production can only be simply deformed parts manufacturers. Cold rolling, after continuous annealing process. Square tube, cold rolled production quality, as well as surface appearance, as well as the accuracy of the size of hot rolled rectangular tube is better than the above, the thickness is much thinner, so has been favored by many manufacturers. Many industries, on the other hand, are very widely used. Many defects of square tube are caused in the perforation process, so the perforation process in the blank is the key procedure in the production of square tube. The main difficulty of high alloy perforation lies in its low perforation performance. Small amount of compression will cause the perforation process is not stable, so the critical pressure shrinkage when the head should be in front of the compression of the general set at about seven percent, otherwise it will not bite, or even move to increase or before the card. An increase in compression in front of the head will also form a cavity and sink defects inside the sound. Therefore, if you want to overcome the problem, the tube blank should be centered, and the empty depth of centering should be compared according to other steel types. Hot-rolled rectangular tubes, continuous casting billets, and rolled plates as raw materials, and then through the heating furnace, even in the use of high pressure water, the surface of phosphorus removal work, and then with a roughing mill, in the roughing mill is mainly cut off the head and tail of the rectangular tubes, and then in the pipeline, and then fed to the finishing mill, computer-controlled precision rolling. After the square tube is cooled by laminar flow, the coiler is rolled and then crimped. However, when re-crimping, the thickness often appears as well as something of an error in accuracy. This is no different from the edges are also prone to flaws. Then crimping again, trim with straightening treatment after the cutting head, after that to ensure the thickness and accuracy of the tube.| SHS/RHS HOLLOW SECTION PIPE SIZE CHART | |||

| Size(MM) | Thickness(MM) | Size(MM) | Thickness(MM) |

| 10*10 | 0.5-1.5 | 15*10 | 0.6-1.0 |

| 15*15 | 0.6-1.5 | 20*10 | 0.6-1.0 |

| 20*20 | 0.6-2.0 | 40*20 | 0.6-3.0 |

| 30*30 | 1.0-2.75 | 60*30 | 1.0-3.75 |

| 40*40 | 1.0-3.5 | 80*40 | 1.5-5.75 |

| 50*50 | 1.0-5.0 | 100*50 | 2.0-6.0 |

| 60*60 | 1.0-6.0 | 120*60 | 3.0-6.0 |

| 70*70 | 1.5-6.0 | 120*80 | 3.0-6.0 |

| 80*80 | 2.0-6.0 | 150*50 | 3.0-6.0 |

| 90*90 | 2.0-6.0 | 150*100 | 4.0-12 |

| 100*100 | 2.3-6.0 | 160*80 | 4.0-6.0 |

| 150*150 | 4.0-6.0 | 200*100 | 4.0-12 |

| 200*200 | 4.0-8.0 | 200*150 | 4.0-12 |

| 250*250 | 6.0-12 | 250*150 | 5.0-12 |

| 300*300 | 6.0-12 | 300*200 | 5.0-12 |

| 400*400 | 6.0-12 | 400*200 | 5.0-12 |

| Other sizes can be customized according to your request | |||

| packing details | Big order: in bulk |

| Small order: packed by steel strips | |

| woven cloth with 7 slats | |

| according to the requirements of customers | |

| 20ft container can load 25 tons, 40ft container can load 26 tons. | |

| Delivery time | 3-15 working days after received the deposit or L/C. |